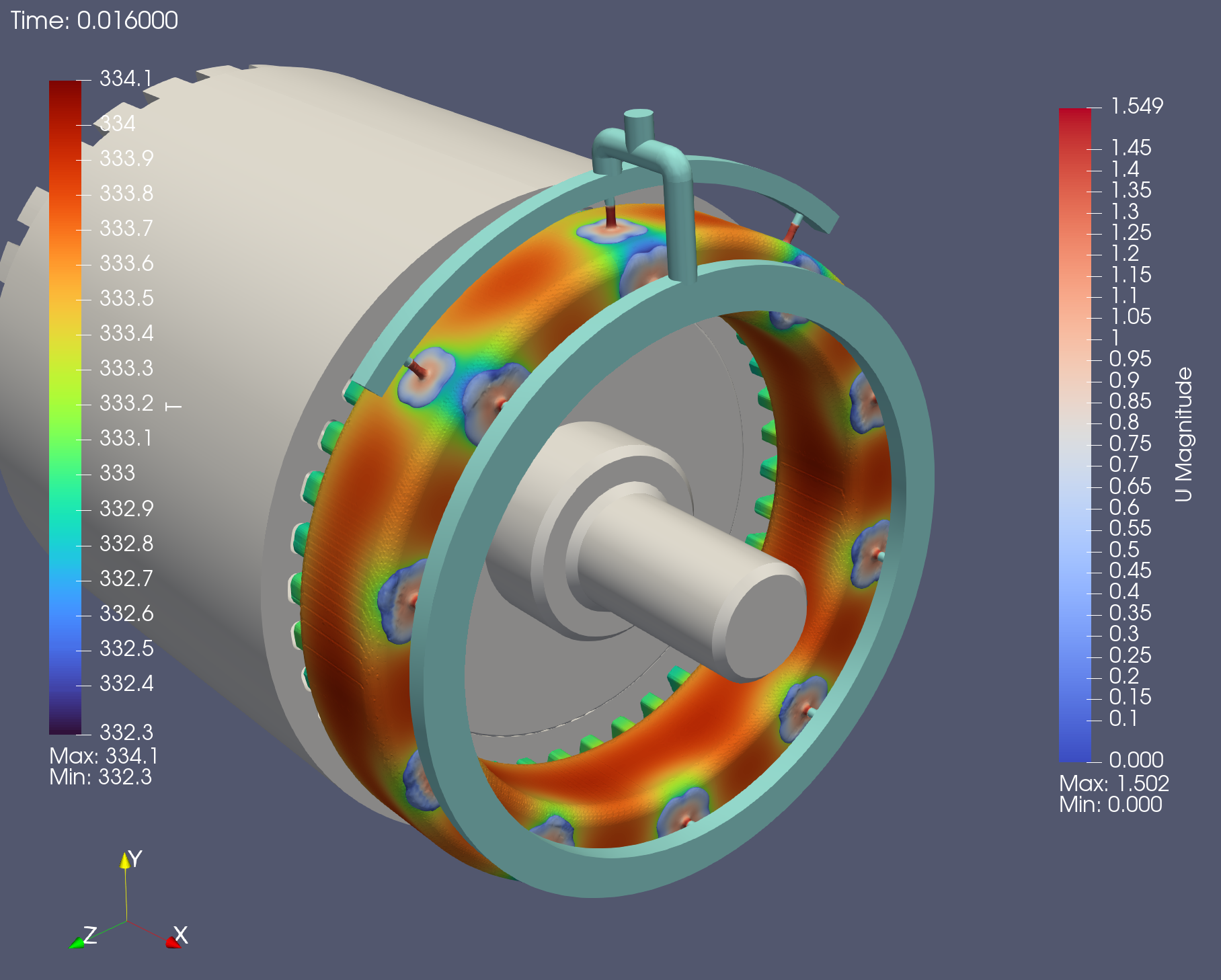

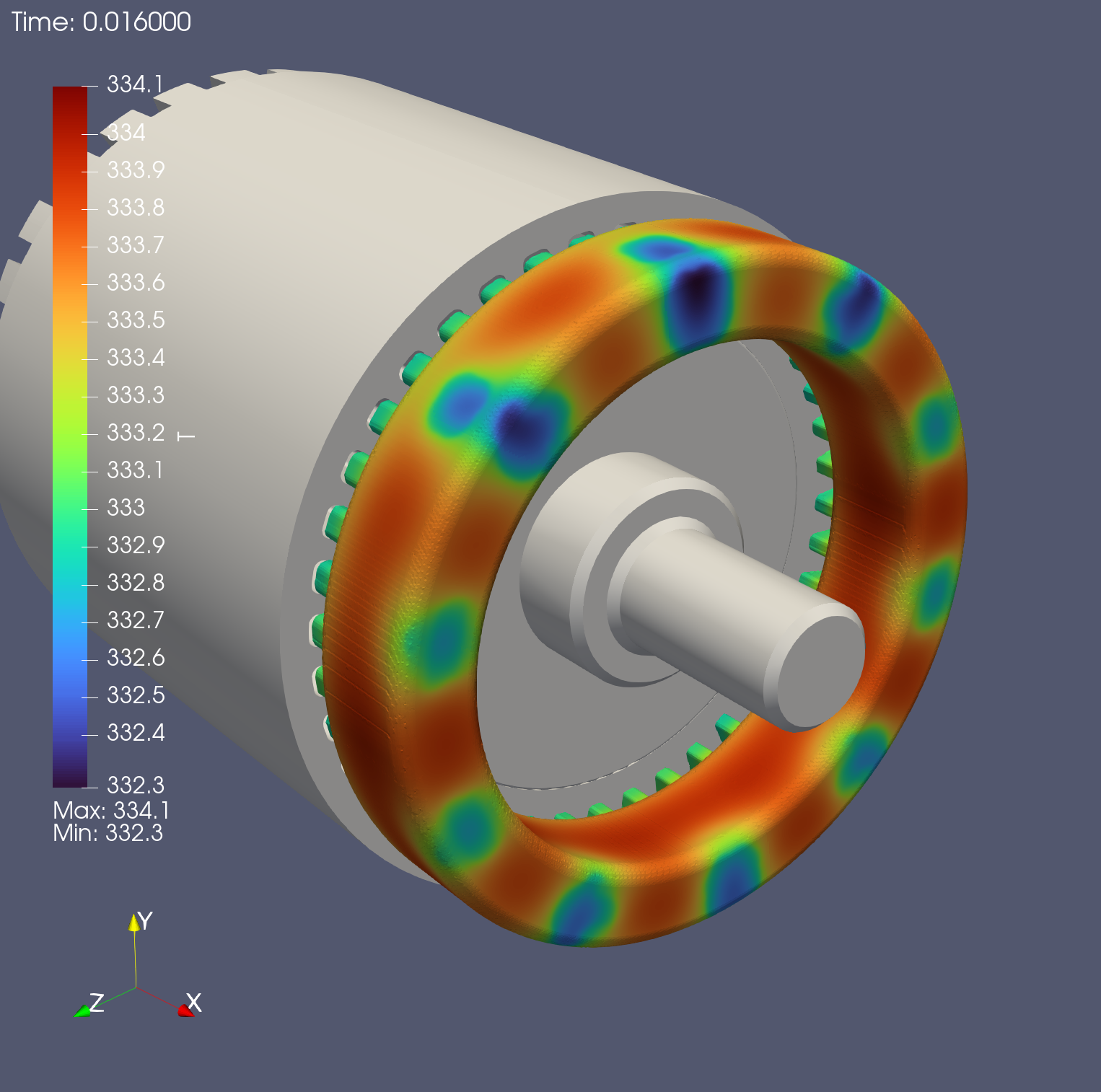

Simulation Visualization

Watch the oil injection cooling simulation in electric motor end winding geometry. This visualization demonstrates the complex multiphase flow patterns and thermal management in high-performance electrical equipment.

Advanced Solver Capabilities

Our team of PhD experts has developed a powerful custom solver specifically engineered for electric motor oil cooling applications, incorporating the latest VOF sharp interface technology to tackle complex multiphase flow and heat transfer challenges in electrical equipment cooling.

Key Capabilities:

- Solid & Liquid Interaction

- Sharp Interface Tracking

- Smart Meshing (AMR)

- Wetting Phenomena (Dynamic Contact Angle)

Advanced Features:

- High Prandtl Fluids & CHT

- Advanced Wall Boundary Treatment

- Thermal Boundary Layer Optimization

- Conjugate Heat Transfer

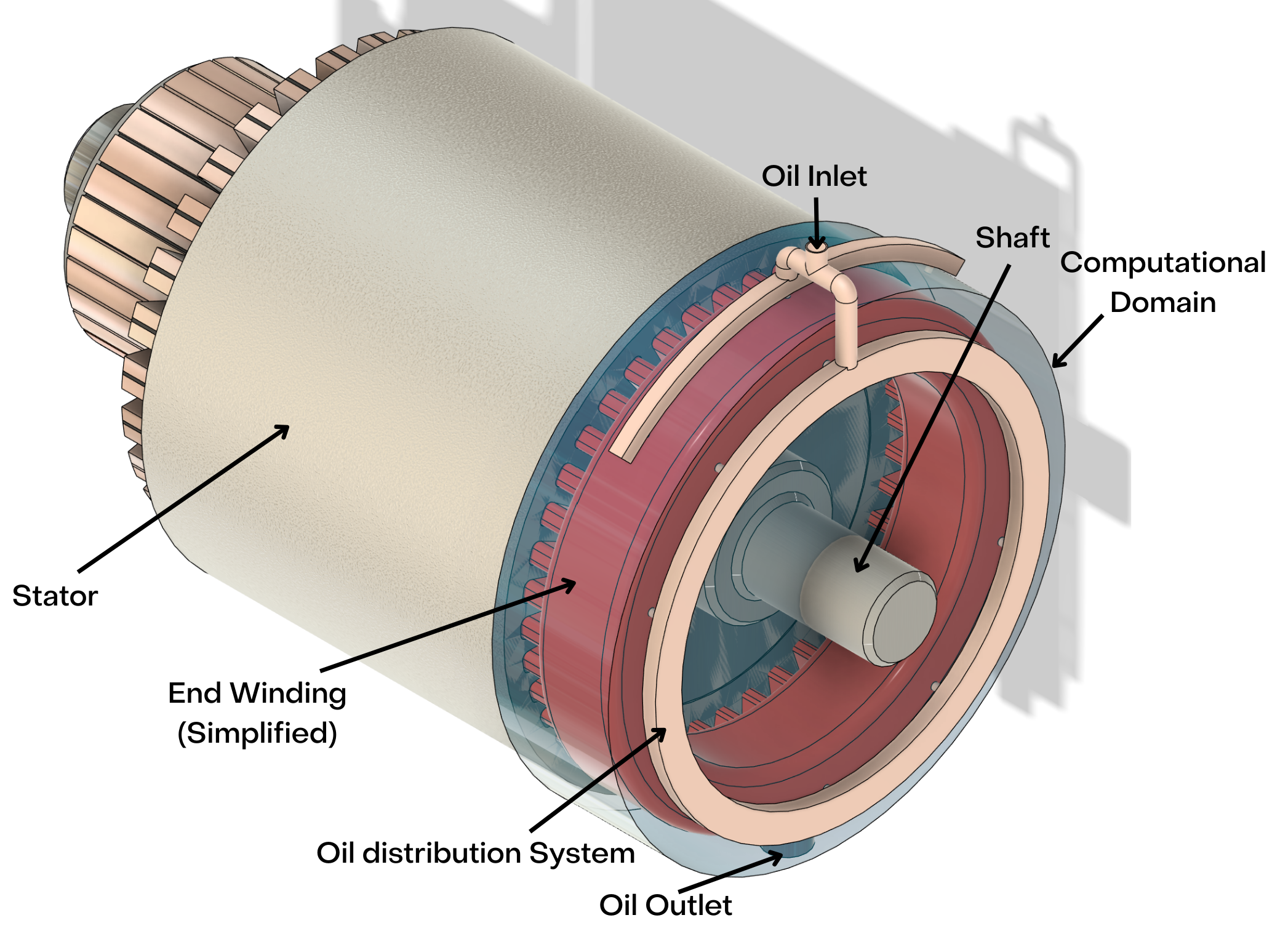

Computational Domain & Geometry

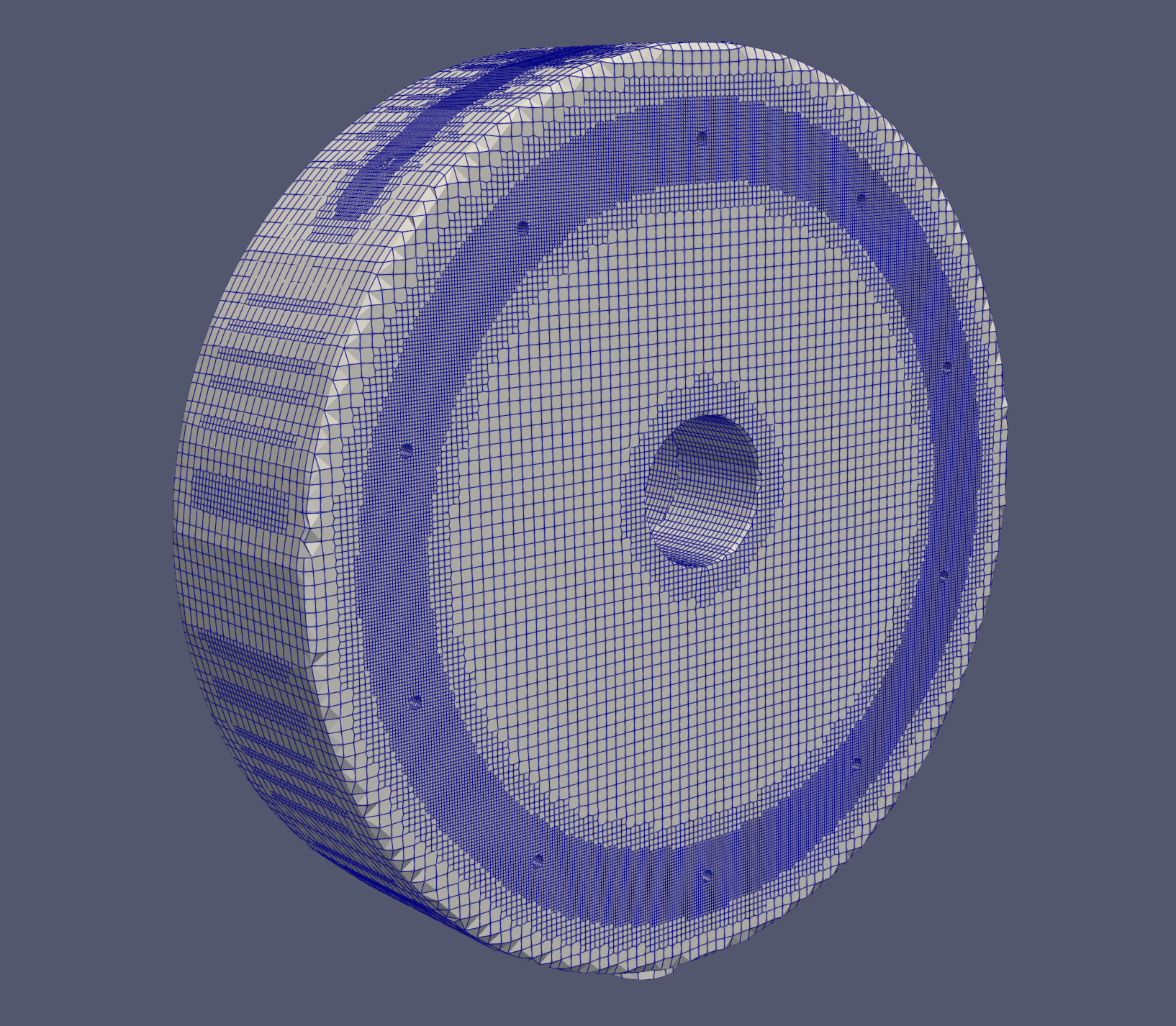

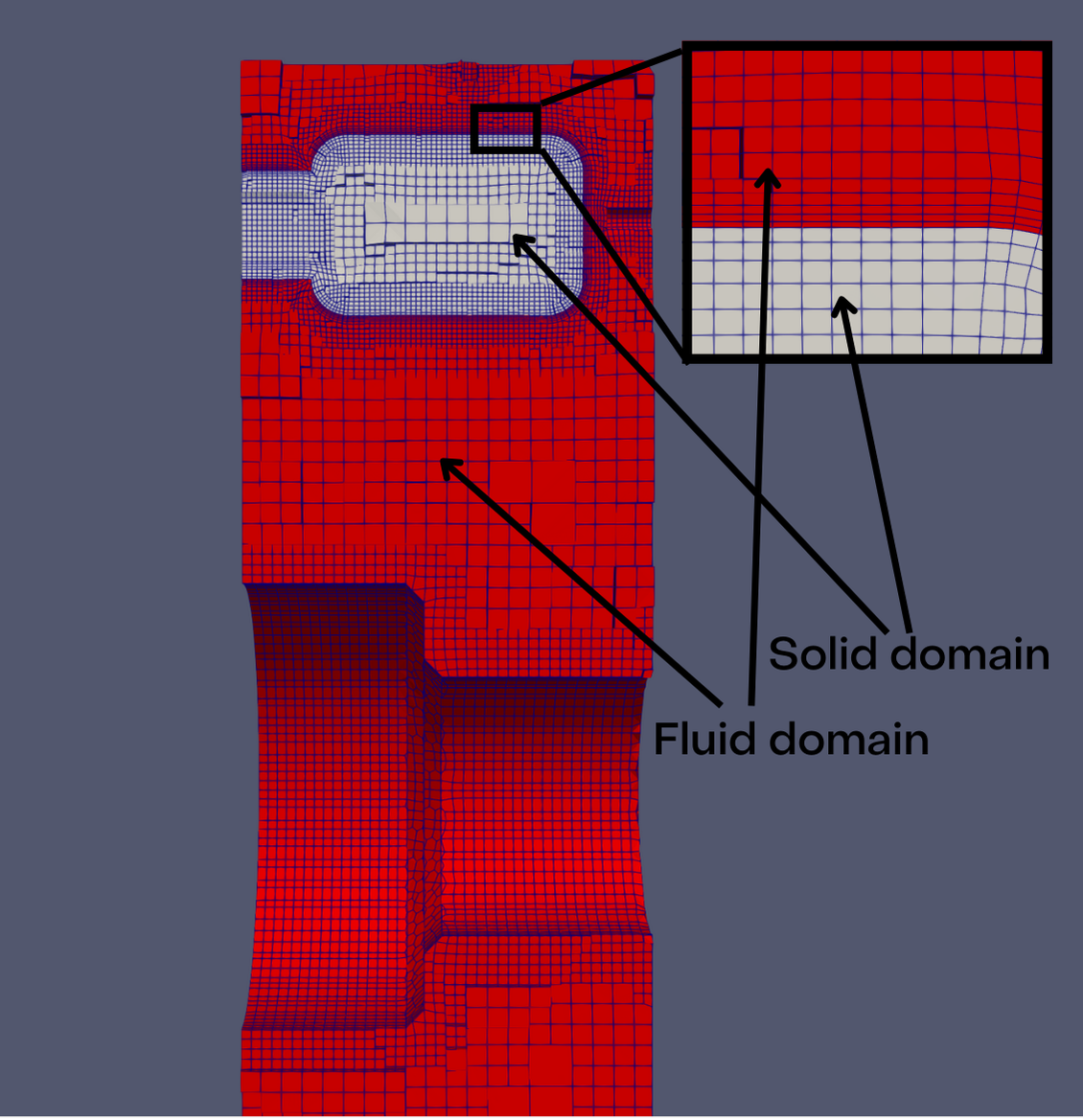

Mesh Generation & Refinement

Simulation Setup & Solver

Technical Specifications

Simulation Results

Methodology & Approach

The simulation employs state-of-the-art computational fluid dynamics techniques to model the complex interaction between oil injection and heat transfer in electric motor end winding systems. The methodology includes:

Conjugate Heat Transfer

Seamless coupling of energy transfer between solid domain (temperature field) and liquid coolant (two-phase flow), capturing real-world physics accurately.

Sharp Interface Tracking

Utilizing the isoAdvector method to resolve the liquid-vapor interface with exceptional sharpness—eliminating blurry, diffused interfaces critical for precise multiphase phenomena prediction.

Smart Meshing

Intelligent focusing of high-resolution cells only where needed most—at critical liquid-vapor interfaces and thermal boundary layers—drastically reducing computational time while preserving accuracy.

Applications & Benefits

This advanced oil injection cooling simulation provides valuable insights for the design and optimization of high-performance electrical equipment, particularly in applications requiring efficient thermal management.

Key Applications:

- Electric Motor Cooling Systems

- Generator Thermal Management

- High-Power Electrical Equipment

- Industrial Cooling Applications

Engineering Benefits:

- Optimized Cooling Performance

- Reduced Thermal Stress

- Enhanced Equipment Reliability

- Improved Energy Efficiency